China operations to play big role in BMW's emissions-cut target

BMW AG is pledging to cut at least 60 million tons of carbon dioxide equivalent by 2035 compared with 2019 levels, with its operations in China expected to play an important role in meeting the goal.

The updated goal marks a new waypoint in BMW's roadmap to achieving net-zero emissions by 2050.

The company already aims to trim lifecycle emissions by at least 40 million tons by 2030, and now expects to halve emissions per euro of revenue by 2035.

BMW said it will rely on a full-lifecycle decarbonization strategy spanning raw-material sourcing, manufacturing, vehicle use and end-of-life recycling.

That includes expanding renewable-energy adoption across production and supply chains, increasing recycled-material content in high-emissions components such as batteries and aluminum, and pushing efficiency gains across all drivetrain types, including its expanding portfolio of electrified vehicles.

China — BMW's largest single market and home to one of its most advanced manufacturing clusters — plays an outsized role in delivering these cuts.

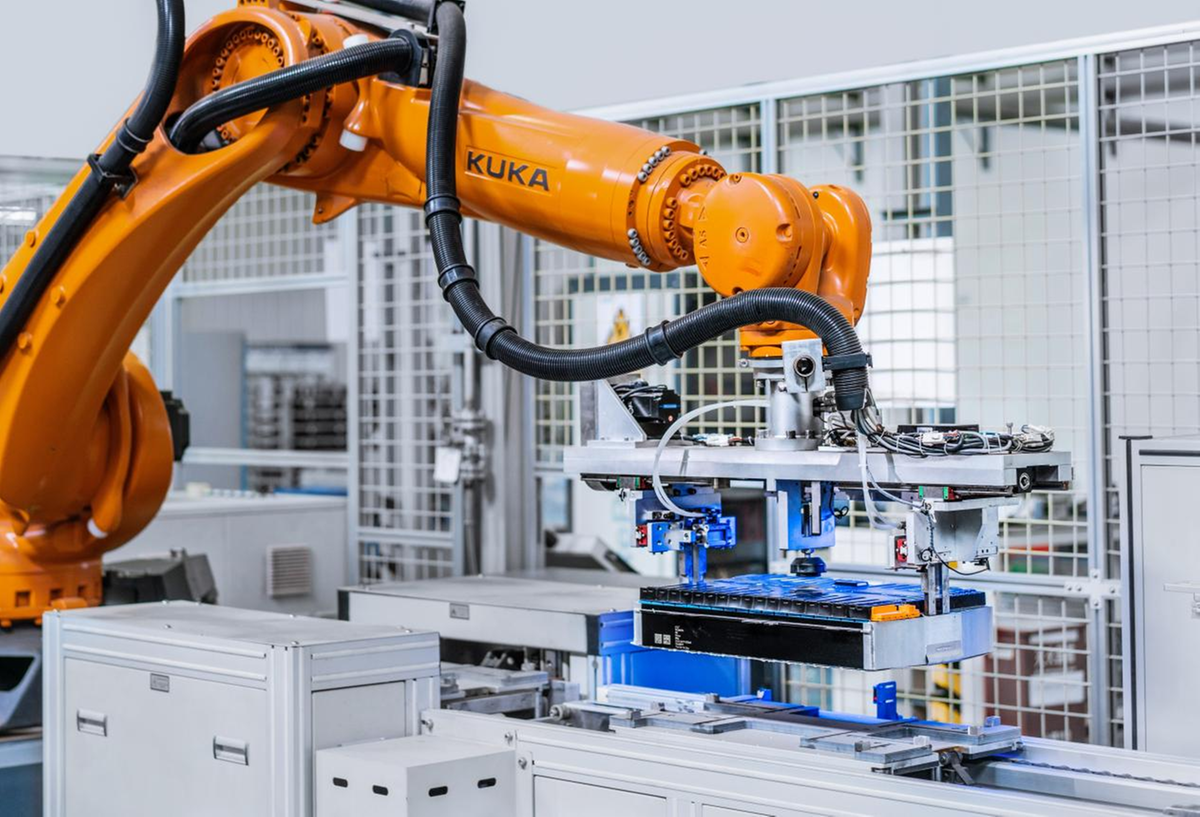

BMW's Shenyang manufacturing hub in Northeast China's Liaoning province has become a cornerstone of the company's global sustainability efforts.

The site has operated entirely on renewable electricity since 2019 and has been named a national-level "Green Factory" for nine consecutive years.

In 2024, its self-built solar capacity generated 91.86 GWh of renewable power — enough to supply roughly 30,000 households for a year.

A new mid-depth geothermal heating project, tapping energy 2,900 meters underground, is expected to reduce annual emissions by about 18,000 tons.

BMW is also mobilizing China-based suppliers as part of its decarbonization push.

About 200 core Chinese suppliers have committed to using green electricity, helping cut supply-chain emissions by roughly 1 million tons in 2024 versus 2019.

The company said it has achieved a 100 percent recycling rate for retired EV batteries in China, recovering more than 2,100 tons of battery materials last year.

On the product side, BMW will launch its next-generation "Neue Klasse" models in China with its sixth-generation eDrive technology, featuring cylindrical cells and an in-house energy-management system designed to reduce losses and improve performance.

The automaker said the manufacturing redesign behind the new models further lowers the vehicles' embedded carbon footprint from the moment they leave the Shenyang line.

BMW is also working with State Grid and other partners to promote renewable-powered public charging. Its joint-venture brand, Ionchi, already supplies charging services using 100 percent green electricity.