Railway network sets new benchmarks

China's HSR focuses on maintenance, overhaul, and full-life cycle services

China's high-speed rail network has evolved into the world's most advanced and extensive system, setting benchmarks in digitalization, safety, and efficiency, according to a senior industry executive.

"We see very high potential to implement some of the cutting-edge digital tools faster in China than we do in other parts of the world, as the country is exceptionally open to adopting new technologies and has a vast pool of skilled talent capable of mastering the tools," said Jonathan Paddison, a member of the board of directors of Knorr-Bremse Asia Pacific (Holding) Ltd, which is a subsidiary of Knorr-Bremse Group, a Munich-based braking systems manufacturer.

After two decades of rapid development, China's railway sector is entering a new phase, he said.

"The industry is shifting from being primarily an original equipment market to becoming a rail services market, one increasingly focused on maintenance, overhaul, and life cycle service," Paddison said.

"Some of the products we see today may have been delivered 20 years ago, so we can modernize and add new digital functions and new software to them. This is a huge opportunity to expand our business here," he said.

In this regard, there is a huge demand for the intelligent digitalization of the railway service sector, which could be very helpful in reducing heavy labor work, improving availability and predictability levels, and facilitating safety control during operations, the executive said.

He added that the current integration trends of artificial intelligence, IoT, and predictive analytics into rail operations also reflect China's ambition to lead the next generation of smart mobility.

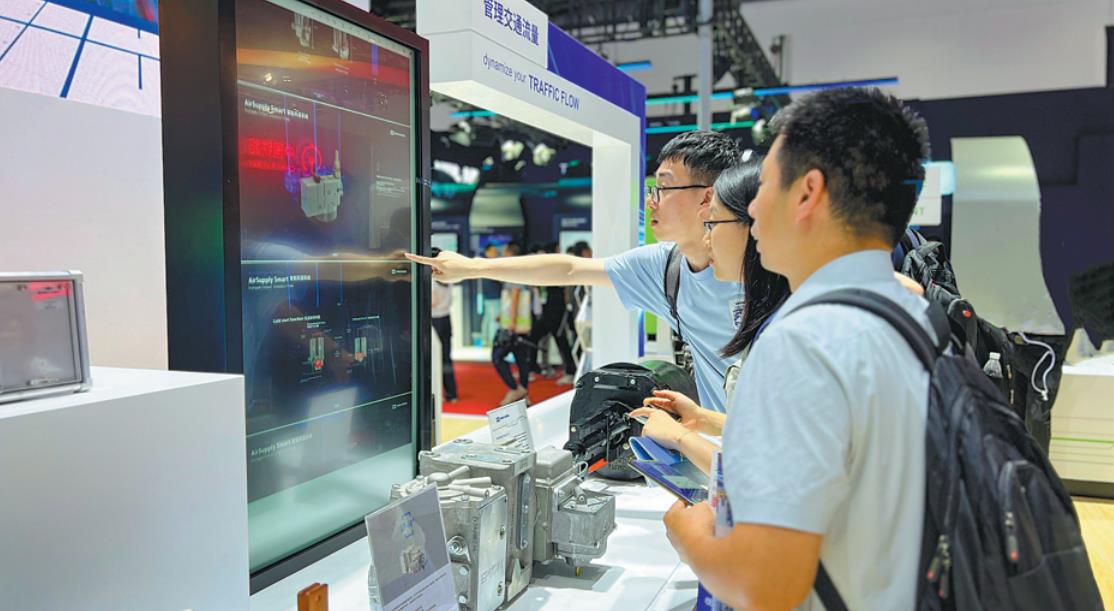

Paddison made the remarks during the 12th UIC World Congress on High-Speed Rail held earlier this month in Beijing.

At the congress' opening ceremony, China State Railway Group Co unveiled a new report on the country's high-speed rail development. As of the end of 2024, China's operational HSR network had reached 48,000 kilometers — more than 70 percent of the global total — and now connects 97 percent of Chinese cities with populations exceeding 500,000.

Data from International Union of Railways (UIC) also showed that the construction and operation of HSR systems have stimulated rapid growth in related sectors such as machinery, precision instruments, rubber and information technology.

UIC estimates suggest that for every 100 million yuan ($13.8 million) invested in HSR, more than 1 billion yuan in output is generated across downstream industries such as construction and metallurgy, creating over 600 jobs in the process.

Rooted in China for over 20 years, Paddison said the group has good experience in developing sub-suppliers in the nation and bringing them step-by-step up to the quality level.

"Over 80 percent of our components are now sourced locally, ensuring cost efficiency and faster delivery," he said, adding that the number is expected to go beyond 95 percent in the next few years.

To further support the Chinese market, Knorr-Bremse has been expanding its innovation and production footprint. It currently operates integrated R&D and manufacturing hubs in Beijing; Suzhou, Jiangsu province; Chengdu, Sichuan province; and Qingdao, Shandong province.

"We're planning new facilities in cities such as Shenzhen of Guangdong province, to provide more responsive, localized service to China's railway operators," Paddison said, noting that these efforts will gradually scale up.